High temperature Sunson® HTAA for starch liquefaction

INTRODUCTION:

Sunson® HTAA High-temperature alpha-amylase is produced by submerged fermentation of a selected strain of Bacillus licheniformis followed by purification and formulation. This product is very thermostable and works under low pH and low calcium content condition. It is widely used for liquefaction in starch processing and fermentation of monosodium glutamate, alcohol, pharmaceutical, beer, organic acid, etc. as well as for “desizing” in textile industry.

DEFINITION OF UNIT:

1 unit of High Temperature α Amylase equals to the amount of enzyme which liquefies 1mg of soluble starch to dextrin at 70℃ and pH6.0 in 1 min.

SPECIFICTIONS

ENZYMATIC ACTIVITY: ≥30,000 u/ml;

≥40,000u/ml

APPERANCE: Liquid

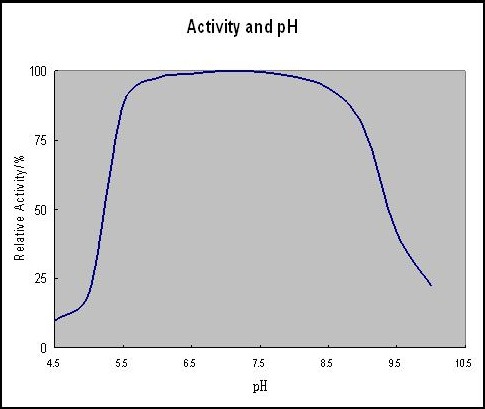

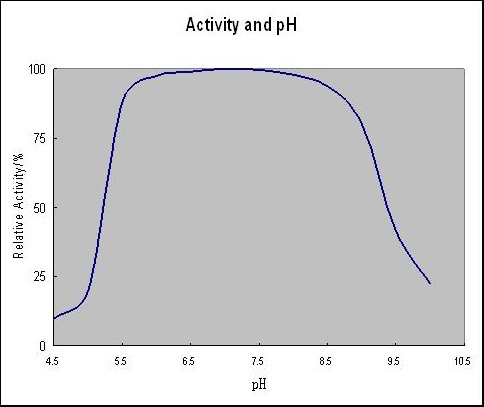

WORKING CONDITION:

Temperature: 80-110℃, favorable at 95-105℃;

pH: 5.5-8.0, optimum 6.0-6.5

FUNCTIONS AND BENEFITS:

Randomly hydrolyze the α-1,4 glycosidic linkages of starch to produce dextrin, a little glucose and maltose, resulting in liquefaction of starch;

Increases malt extract yield during mashing and help with adjunct cooking in brewing;

Produce low-viscosity dextrose syrups;

Decrease formation of non-fermenting sugars;

Make fermentation faster and reduce processing time;

Make the liquefaction of different starch materials such as tapioca, corn, wheat and rice much more effective;

Very stable under low pH environment, and resistant to high temperature.

APPLICATION:

1.In alcohol industry: the recommended dosage is 0.3kg per ton raw material at pH 6.5-7.0, pumped in cooking boiler or continuously spray liquefaction heater after mixed, maintain pot temperature at 93-97 degrees for around 60-100 mins, instantaneous temperature can reach to 100±5 degrees, saccharification after cool off.

2.In beer industry: The recommended dosage is 0.3kg around per ton material then liquefy 30 mins at temperature of 95-97 degrees.

3.In starch sugar industry: mix starch and water to the right consistency, adjust ph value 6.5-7.0 and add 0.15% - 0.2% calcium chloride, and then add this enzyme 0.6kg (20000u/g) per ton material. For interlude liquefy, increase tank temperature to 95-97 degrees rapidly and liquefying 30-60 mins; for spray liquefy, instantaneous temperature can reach to 100±5 degrees and keep temperature at 95-97 degrees for 60-120 mins.

PACKAGE:

Powder products: 25kgs/bag.

Liquid products: 25kgs/drum or 1125kgs/drum

STORAGE:

Should be stored in a cool, dry and cool place.

SHELFLIFE:

Powder products: 25℃, 12 months, enzymatic activity remains ≥95%.

Liquid products: 25℃, 6 months, enzymatic activity remains≥90%.

SAFETY:

| E-mail: sunson@chinaenzymes.com |

| Tel:86-20-86586087 86-10-58246891 |

| Fax:86-20-86586895 86-10-58246862 |