Glucose amylase Sunson® GA for saccharification

INTRODUCTION:

Sunson® GA is a glucoamylase (Glucan 1,4-α-glucosidase) made from Aspergillus niger by submerged fermentation and purification. it's often used for the saccharification process in starch sugar processing or fermentation industry like the fermentation of alcohol, spirits, beer, organic acid, antibiotic and so on. Glucoamylase can catalyze the hydrolysis of starch. It decomposes alpha-1,4 glucosidic linkage from the non-reductive end of a starch molecule so as to form glucose. The enzyme is often used together with alpha-amylase.

DEFINITION OF UNIT:

1 unit of glucoamylase equals to the amount of enzyme which hydrolyzes soluble starch to get 1 mg glucose at 40 ºC and pH 4.6 in 1 hour.

ENZYMATIC ACTIVITY ≥130,000u/ml(u/g);

≥150,000u/ml(u/g)

APPERANCE: Brown (liquid type); Yellowish-brown (powder type)

WORKING CONDITION:

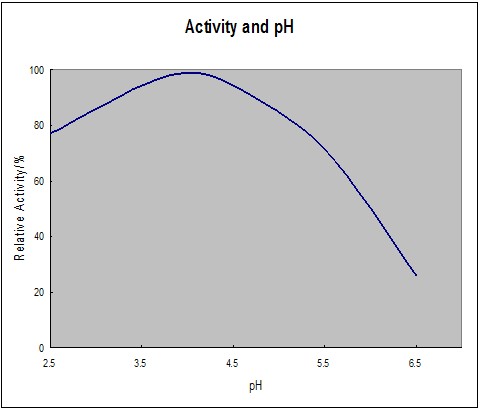

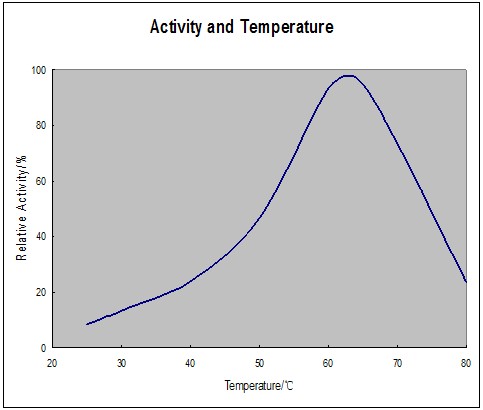

Temperature: 40~65℃, favorable at 58~60℃;

pH: 3.0~5.5, optimum 4.0~4.5

FUNCTIONS AND BENEFITS:

Glucoamylase can splits α-1,4 glycosidic bond of starch from non-reducing end to produce glucose and also can slowly hydrolyze α-1,6 glycosidic bond. At the branch ofα-1,6 bond, it slices off α-1.6 bonds first then α-1.4 bonds. Generally speaking, it can be used in any industries in which starch and dextrin have to be hydrolyzed by enzymes

APPLICATION:

Ethanol industry: Cooling the raw materials to 60℃ after the steam cooking, then adjust the PH to 4.0-4.5, adding glucoamylase, the suggested dosage is 80-200u/ml, keeping the temperature 30-60 minutes, after the cooling, the fermentation process will begin.

Starch Syrup industry: Cooling the raw materials to 60℃ after liquefaction, then modulate the PH to 4.0-4.5, adding glucoamylase,the suggested dosage is 100-300u/ml, keeping the temperature for saccharification.

Beer industry: Adding the glucoamylase during mashing or fermentation to increase fermentation degree.

Liquor industry: For the process of the spirit, millet wine, glucoamylase can reduce fermentation time and improve yield.

PACKAGE:

Powder products: 25kgs/bag.

Liquid products: 25kgs/drum or 1125kgs/drum

STORAGE:

Should be stored in a cool, dry and cool place.

SHELFLIFE:

Powder products: 25℃, 12 months, enzymatic activity remains ≥95%.

Liquid products: 25℃, 6 months, enzymatic activity remains≥90%.

SAFETY:

Enzyme preparations belong to protein, which may induce sensitization and cause allergic type reactions in sensitized individuals. Prolonged contact may cause minor irritation for skin, eyes or mucous membrane of nose, so any direct contiguity with human body should be avoided. If irritation or allergic response for skin or eyes develops, consult a doctor.

| E-mail: sunson@chinaenzymes.com |

| Tel:86-20-86586087 86-10-58246891 |

| Fax:86-20-86586895 86-10-58246862 |