Food grade glucose oxidase enzymes

This product is produced by submerged fermentation of Aspergillus niger followed by purification, formulation and drying. The highly stable potent product is widely used in gluconic acid production, flour whitening, baking, medical applications and in many other industries.

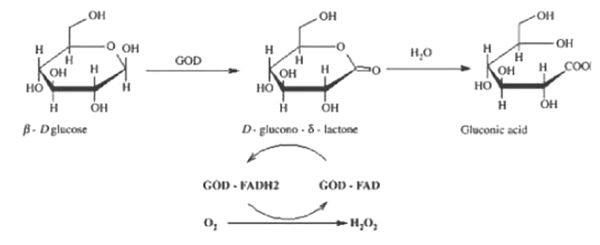

MECHANISM

Glucose Oxidase can specifically catalyze β-D-glucose to form gluconic acid and hydrogen peroxide with the presence of oxygen.

A: C6H12O6+ O2 + H2O → C6H12O7 + H2O2

B: C6H12O6+ 1/2 O2 →C6H12O7

REACTION PARAMETERS

|

CONDITION |

RANGE |

|

Activity Temperature |

25℃-60℃ |

|

Optimum Temperature |

30℃-40℃ |

|

Activity pH |

3.0-7.0 |

|

Optimum pH |

5.5-6.3 |

The product complies with GB1886.174.

|

No. |

ITEMS |

INDEX |

|

|

1 |

Particle size (%<40 mesh) |

≥80 |

|

|

2 |

≤8.0 |

||

|

3 |

Lead/(mg/kg) |

≤5.0 |

|

|

4 |

Arsenic/(mg/kg) |

≤3.0 |

|

|

5 |

Total viable count/(CFU/g) |

≤50000 |

|

|

6 |

Coliform Bacteria/(CFU/g) |

≤30 |

|

|

7 |

Escherichia coli |

(CFU/g) |

<10 |

|

(MPN/g) |

≤3.0 |

||

|

8 |

Salmonella/(25g) |

Not Detected |

|

White to light yellow powder. Color may vary from batch to batch. Color intensity is not an indication of enzyme activity.

The recommended dosage is 0.01-1.5kg/t DS. The dosage has to be optimized based on each application, the raw material specifications, product expectation and processing parameters. It is better to begin the test with the convenient volume.

Enzyme preparations are proteins that may induce sensitization and cause allergic type of symptoms in susceptible individuals. Prolonged contact may cause minor irritation for skin, eyes or nasal mucosa. Any direct contact with human body should be avoided. If irritation or allergic response for skin or eyes develops, please consult a doctor.

WARNINGS

PACKAGE AND STORAGE

Ø Package: 25kg/drum.

Ø Storage: Keep sealed in a dry and cool place and avoid direct sunlight.

Ø Shelf life: 12 months in a dry and cool place.

| E-mail: sunson@chinaenzymes.com |

| Tel:86-20-86586087 86-10-58246891 |

| Fax:86-20-86586895 86-10-58246862 |