Food additive enzyme transglutaminase for protein cross linking

PRODUCT DESCRIPTION

This product is produced by submerged fermentation of Streptomyces mobaraensis followed by purification and formulation. In the food industry, TG is applied in many segments to improve functional properties of meat and protein products, such as improving the meat’s structure, gel characteristic, elasticity, keeping the water and fat, and so on. At the same time, the lysine is protected from maillard reaction.

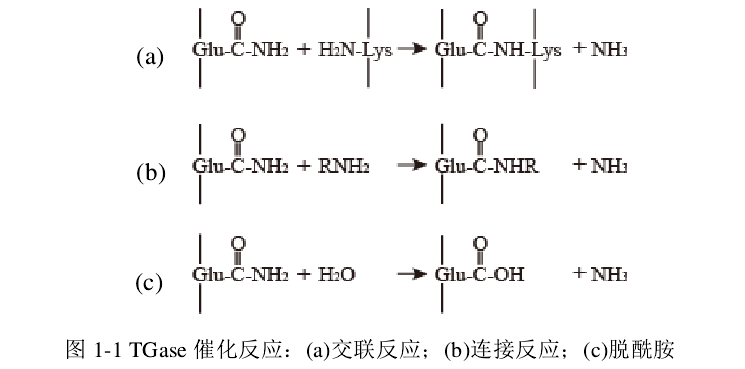

MECHANISM

Transglutaminase (TG) is an enzyme which can catalyze the reaction of transamination. It catalyzes the L-Lysine’s γ-aroylamino-hydroxybutyrate binding to the glutamic acid. So, the covalent crosslinking among the proteins or peptides happens and the polymer of covalent compounds is formed as described in the following diagram:

BENEFITS

1. Emulsion-based meat processing products. (e.g. Sausage, Ham, Hotdog, Salami, etc.)

l Increases gel strength.

l Facilitates water retention and juiciness.

l Improves elasticity and texture of products.

l Increases slice-ability to decrease waste in chopping.

2. Restructured meat products

l Increase slicing effectiveness.

l End product with freewheeling shapes.

l Once restructured, the product can be cooked or frozen without losing shape.

l Create strong bonds between proteins.

3. Dairy products

l Capture more proteins from whey to Increase the yield of cheese products about 10%.

l Increase slice-ability and improve cheese firmness.

l Increase gel strength and viscosity optimize thickening in yoghourt products.

l Reduce syneresis with a smoother surface.

4. Surimi-based products. (e.g. Fishball, Fish cake etc.)

l Increase gel strength.

l Improve elasticity and firmness of fishball

l Improve the physical properties of fishball.

l Facilitate the incorporation of mechanically deboned fish (MDF) into standardized portions with high added value.

REACTION PARAMETERS

|

CONDITION |

RANGE |

|

Activity Temperature |

0℃-65℃ |

|

Optimum Temperature |

50℃-60℃ |

|

Activity pH |

5.0-8.0 |

|

Optimum pH |

6.0-7.0 |

PRODUCT STANDARD

The product complies with GB1886.174.

|

No. |

ITEMS |

INDEX |

|

|

1 |

Particle size (% <40 mesh) /(%) |

≥80 |

|

|

2 |

≤8.0 |

||

|

3 |

Lead/(mg/kg) |

≤5.0 |

|

|

4 |

Arsenic/(mg/kg) |

≤3.0 |

|

|

5 |

Total viable count/(CFU/g) |

≤50000 |

|

|

6 |

Coliform Bacteria/(CFU/g) |

≤30 |

|

|

7 |

Escherichia coli |

(CFU/g) |

<10 |

|

(MPN/g) |

≤3.0 |

||

|

8 |

Salmonella/(25g) |

Not Detected |

|

PRODUCT SPECIFICATION

white powder. Color can vary from batch to batch. Color intensity is not an indication of enzyme activity.

APPLICATION RECOMMENDATION

The dosage has to be optimized based on each application, the raw material specifications, product expectation and processing parameters. It is better to begin the test with the smallest quantity. The covalent bond formed by TGase is hard to split by non-enzymic means. Once the treated minced meat is shaped, the shape is set and resistant to freezing or slicing or cooking.

SAFETY AND HANDLING PRECAUTIONS

Enzyme preparations are proteins, which may induce sensitization and cause allergic type reactions in susceptible individuals. Prolonged contact may cause minor irritation for skin, eyes or nasal mucosa, so any direct contiguity with human body should be avoided. If irritation or allergic response for skin or eyes develops, consult a doctor.

WARNINGS

Kept sealed after use every time to avoid inactivation until its finish.

PACKAGE AND STORAGE

Ø Package: 25kg/drum.

Ø Storage: Keep sealed in a dry and cool place and avoid direct sunlight. Slight sedimentation is acceptable since it will not impact performance of the product.

Ø Shelf life: 12 months in a dry and cool place.

| E-mail: sunson@chinaenzymes.com |

| Tel:86-20-86586087 86-10-58246891 |

| Fax:86-20-86586895 86-10-58246862 |