Neutral cellulase enzyme for textile biopolishing Conzyme NL ULTRA

PRODUCT DESCRIPTION

Conzyme® NL Ultra is a high concentrated liquid neutral cellulase preparation. It is specially developed for fabric and garment biopolishing under neutral condition; it can be added during hydrogen peroxide removal process the same dye bath, and is exclusively designed for formulator.

MECHANISM

Cellulose is a glucose polymer linked with β-1,4-glycosidic bonds. Cellulase system consists of three major components: endoglucanase (endo-1,4-β-D-glucanase or EG), cellobiohydrolases (exo-1,4-β-D-glucanases, or CX, or CBH), and β-glucosidases (1,4-β-D-glucosidase; BG; BGL). These activities work synergistically on cellulose and efficiently convert cellulose into glucose. The product is so designed as to help with enzymatic biopolishing of fabric and garment.

ENZYME PROPERTIES

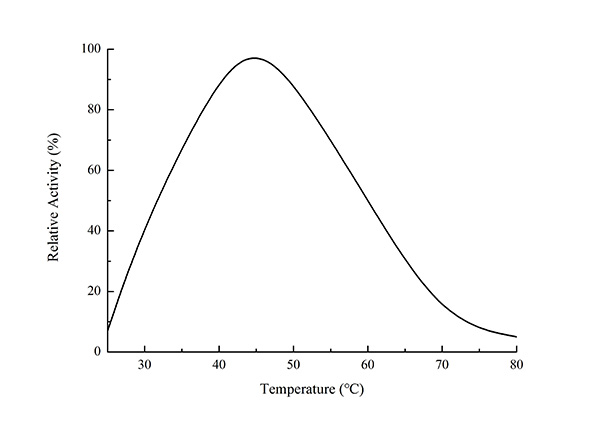

Temperature profile

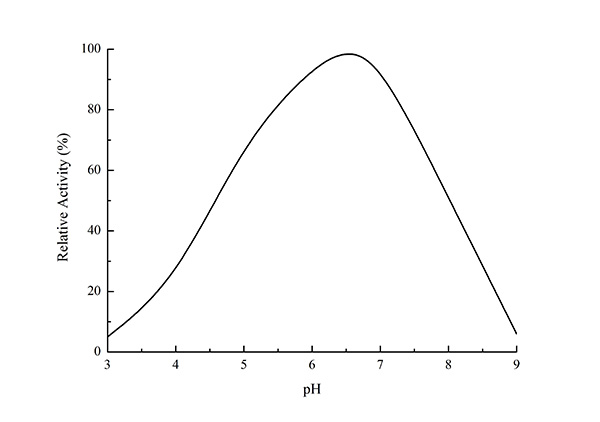

pH profile

PRODUCT SPECIFICATION

|

Items |

Description |

|

Declared Activity* |

5,000u/mL |

|

Physical Form |

Liquid |

|

Color** |

Light yellow |

|

Odour |

Normal microbial fermentation odour. |

|

Solubility |

Soluble in water |

|

CAS NO. |

9012-54-8 |

|

IUB NO. |

EC 3.2.1.4 |

*Definition of Unit: 1 unit of CMCase equals to the amount of enzyme, which hydrolyzes CMC-Na to get 1 μg of reducing sugar (in glucose) in 1 minute. at 50℃ and pH6.0.

** Color: Color can vary from batch to batch. Color intensity is not an indication of enzyme activity.

APPLICATION RECOMMENDATION

Ø Reaction parameters

|

PARAMETERS |

RANGE |

|

Activity Temperature |

20-70℃ |

|

Optimum Temperature |

40-60℃ |

|

Activity pH |

5.5-7.5 |

|

6.0-7.0 |

Ø Application

Temperature: 40-60℃, optimum 45-50℃

Ph: 5.5-8.0, optimum 6.0-7.0

Liquor ratio: 5:1-20:1

Dosage: 0.1-0.3% owg

Time: 30-60 minutes

The dosage has to be optimized based on each application, the raw material specifications, product expectation and processing parameters. It is better to begin the test with the convenient volume.

Ø Inactivation

The enzyme is inactivated at temperature above 80℃ for 10 minutes, or at pH above 8.0 for 10 minutes.

BENEFITS

1. Excellent bio-polishing effect

2. Clean and even fabric surface

3. Softer hand feel

4. Brighter colors

5. Environmental-friendly and Bio-degradable

SAFE HANDLING PRECAUTIONS

Enzyme preparations are proteins that may induce sensitization and cause allergic type of symptoms in susceptible individuals. Prolonged contact may cause minor irritation for skin, eyes or nasal mucosa. Any direct contact with human body should be avoided. If irritation or allergic response for skin or eyes develops, please consult a doctor.

WARNINGS

PACKAGE AND STORAGE

Ø Package: 25kgs/drum; 30kgs/drum

Ø Storage: Keep sealed in a dry and cool place and avoid direct sunlight. Slight sedimentation is acceptable since it will not impact performance of the product.

Ø Shelf life: 9 months in a dry and cool place.

| E-mail: sunson@chinaenzymes.com |

| Tel:86-20-86586087 86-10-58246891 |

| Fax:86-20-86586895 86-10-58246862 |