Alkaline pectinase for textile Conzyme SPA-5

PRODUCT DESCRIPTION

Conzyme® SPA-5 is a liquid and alkaline pectinase preparation. It is specially developed for bioscouring process of knitted natural cellulosic fibers such as cotton, linen, hemp and blend. It removes pectin and other impurities from cotton fibers without any degradation of the cellulose, softens and eliminates cotton seed to optimize dyeing performance.

MECHANISM

Different types of pectinases (PG, PE and PL) are involved in the product to ensure its efficient degradation of pectin and thus remove the impurities in natural cellulosic fibers.

ENZYME PROPERTIES

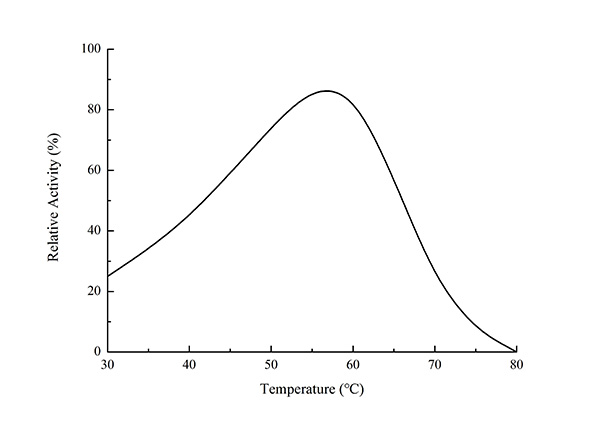

Temperature profile

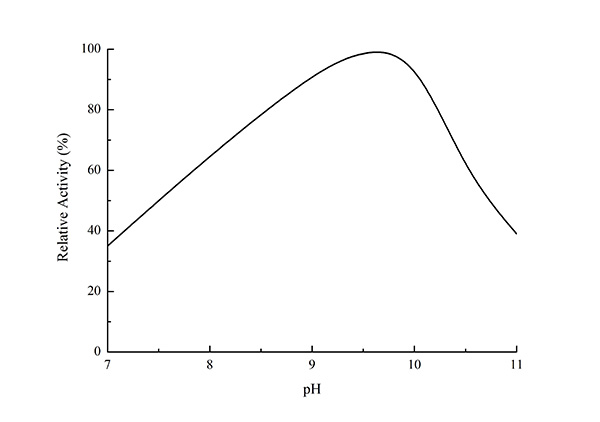

pH profile

PRODUCT SPECIFICATION

|

Items |

Description |

|

Declared Activity* |

10,000APLu/ml |

|

Physical Form |

Liquid |

|

Color** |

Brown |

|

Odour |

Normal microbial fermentation odour. |

|

Solubility |

Soluble in water |

|

CAS NO. |

9032-75-1 |

Definition of Unit: 1 unit of Alkaline Pectinase equals to the amount of enzyme, which hydrolyzes Polygalacturonic acid to get 1 mol of unsaturated Polygalacturonic acid in 1 min. at 45℃ and pH9.4

** Color: Color can vary from batch to batch. Color intensity is not an indication of enzyme activity.

APPLICATION RECOMMENDATION

Ø Reaction parameters

|

PARAMETERS |

RANGE |

|

Activity Temperature |

45-65℃ |

|

Activity pH |

7.0-10.0 |

Ø Application

The recommend dosage is 0.5-1g/L, and the treatment should last for 30-60 minutes.

Temperature: 45-65℃

pH: 7.0-10.0

Liquor ratio: 1:8-1:20

Dosage: 0.5-1g/L

Time: 30-60 minutes

The dosage has to be optimized based on each application, the raw material specifications, product expectation and processing parameters. It is better to begin the test with the convenient volume.

Ø Inactivation

The enzyme is inactivated at temperature above 80℃ for 10 minutes, or at pH above 11.0 for 10 minutes.

BENEFITS

1. A perfect alternative to the traditional process of dyeing and finishing. It can replace the caustic soda, bleaching stabilizer and other harsh chemicals, which simplifies production process and remarkably shortens processing time while reducing TDS、COD、BOD level in waste water.

2. Improved hand feel and softness of fibers

3. No cellulose fibre damage and reduced weight loss of the fibers

4. Water and energy saving

5. Environmentally friendly without extensive use of harsh chemicals

6. Better to be used in combination with anti-pilling process.

SAFE HANDLING PRECAUTIONS

Enzyme preparations are proteins that may induce sensitization and cause allergic type of symptoms in susceptible individuals. Prolonged contact may cause minor irritation for skin, eyes or nasal mucosa. Any direct contact with human body should be avoided. If irritation or allergic response for skin or eyes develops, please consult a doctor.

WARNINGS

PACKAGE AND STORAGE

Ø Package: 25kgs/drum; 30kgs/drum

Ø Storage: Keep sealed in a dry and cool place and avoid direct sunlight. Slight sedimentation is acceptable since it will not impact performance of the product.

Ø

Shelf life: 9 months in a dry and cool place.

| E-mail: sunson@chinaenzymes.com |

| Tel:86-20-86586087 86-10-58246891 |

| Fax:86-20-86586895 86-10-58246862 |